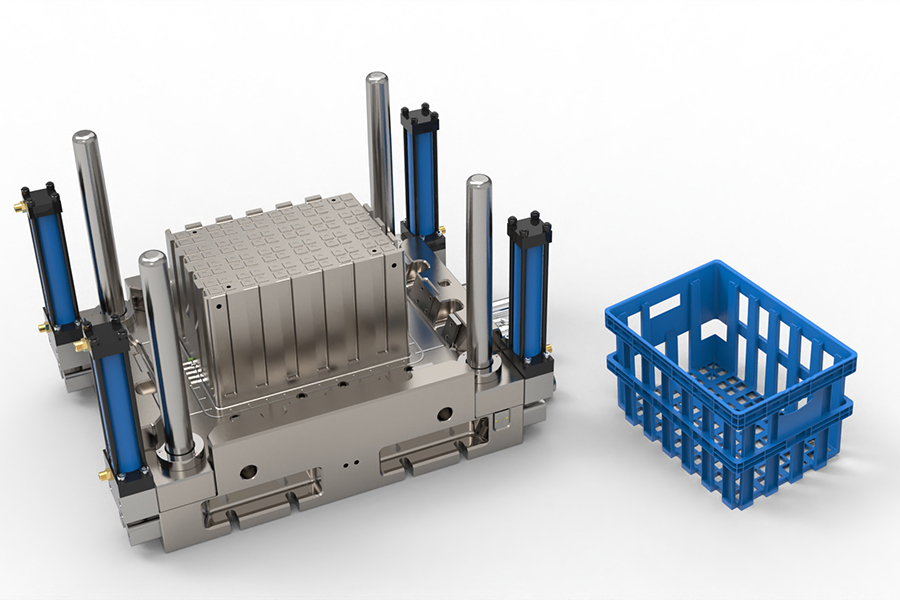

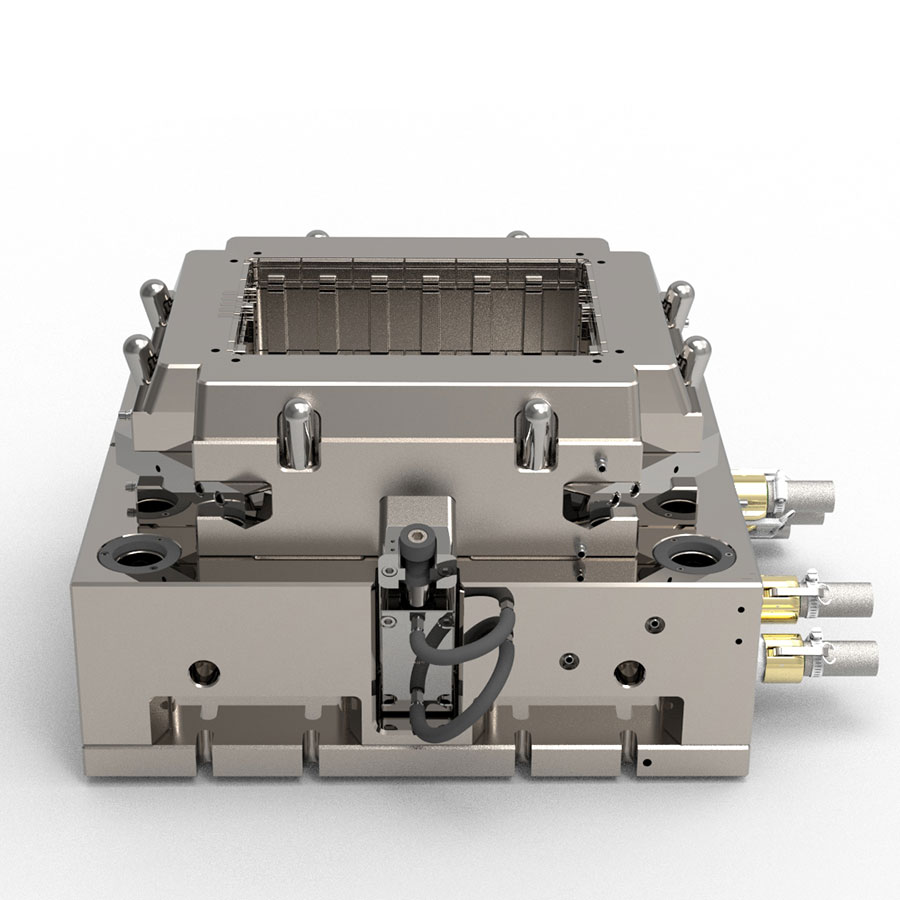

Plastic Crate Mould

- Mould Material: 718 & H13

- Runner System: 6 Point Hot Runner

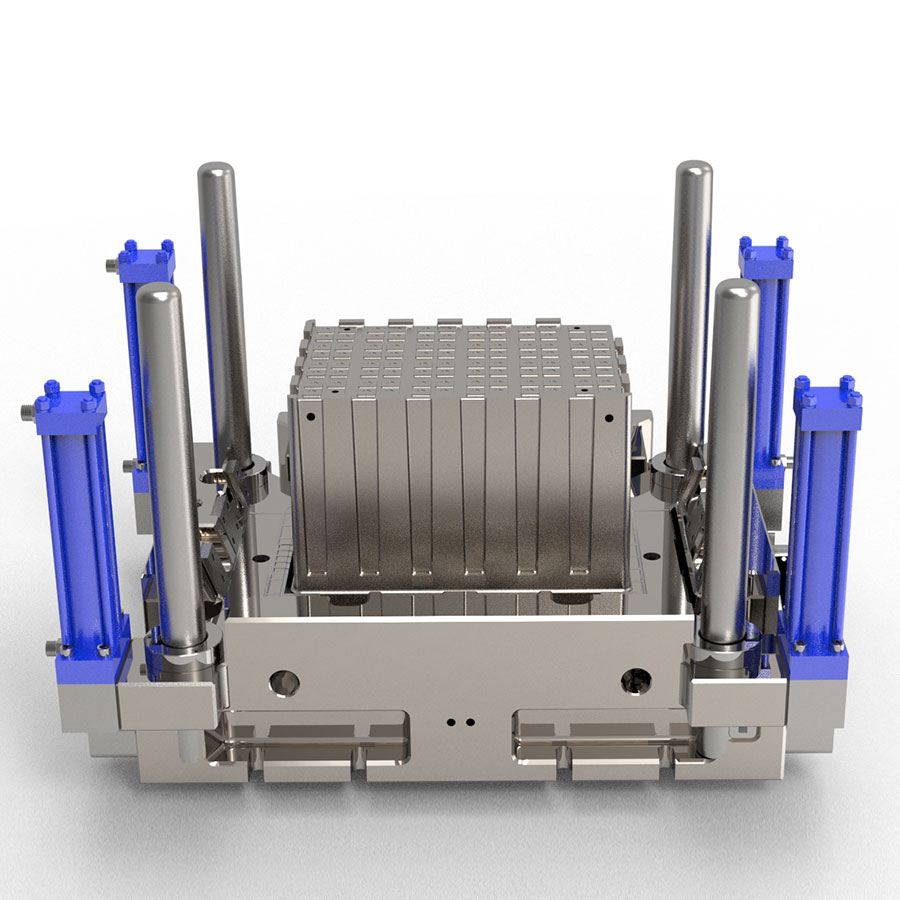

- Mould Structure: Oil cylinder slider

- Cycle Time: 45s

- Injection Machine: 800T

- Ejection System: Ejection of stripper

- Delivery Time: 55-60days

Crate Mold Introduction

The product design points of plastic trash can are demoulding inclination, shrinkage rate and thickness uniformity. The trash can mold applied by manufacturers must be designed to ensure product demoulding and efficient production. The trash can mold should have reasonable slope, so that the trash can body will not stick in the trash can when taken out from the mould, and it is easy to take out trash cans with different shapes. In addition, the trash can mold should also have proper shrinkage rate, which affects the appearance and size of trash cans. The trash can mold must strictly control the thickness uniformity of trash cans, so that the trash cans produced are neat, beautiful and accurate in size. These all contribute to improved user experience when trash cans are used. With optimized trash can mold, trash cans can be produced with high quality and lower production cost.

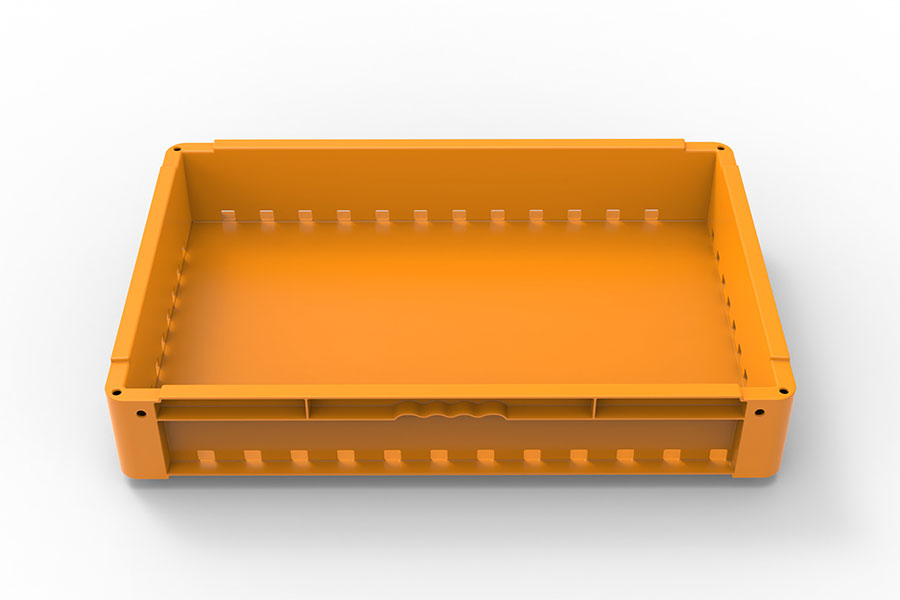

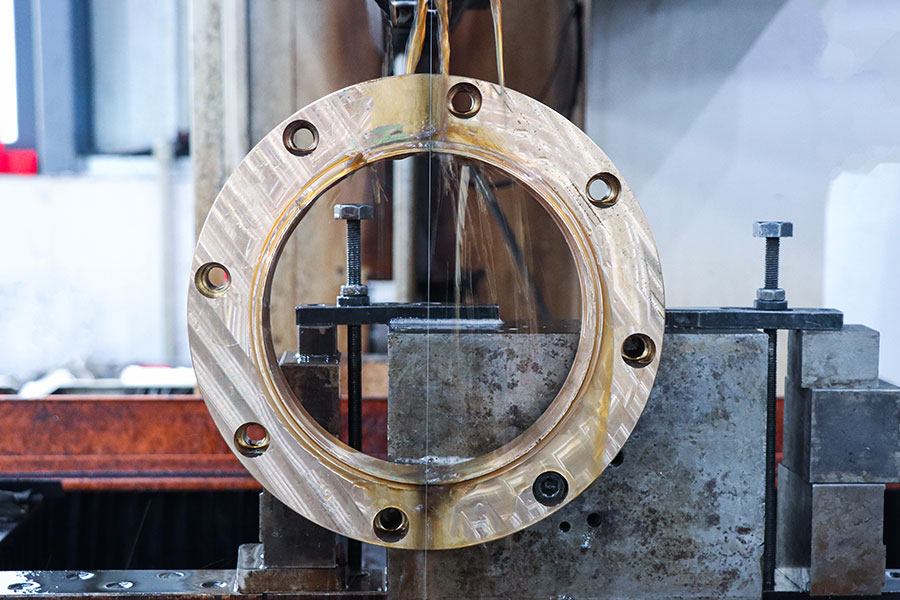

Crate Mold Cavity

Plastic Crate

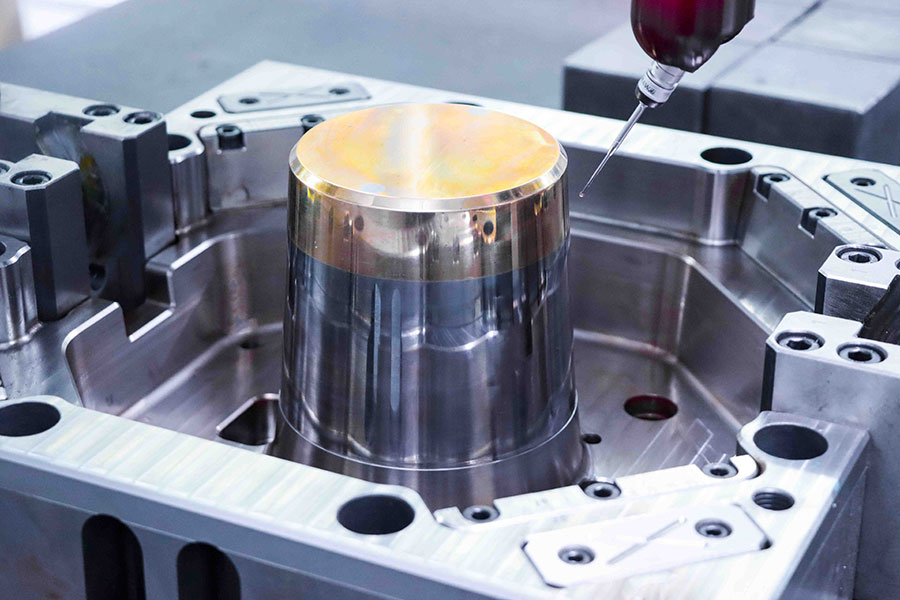

Crate Mold Core

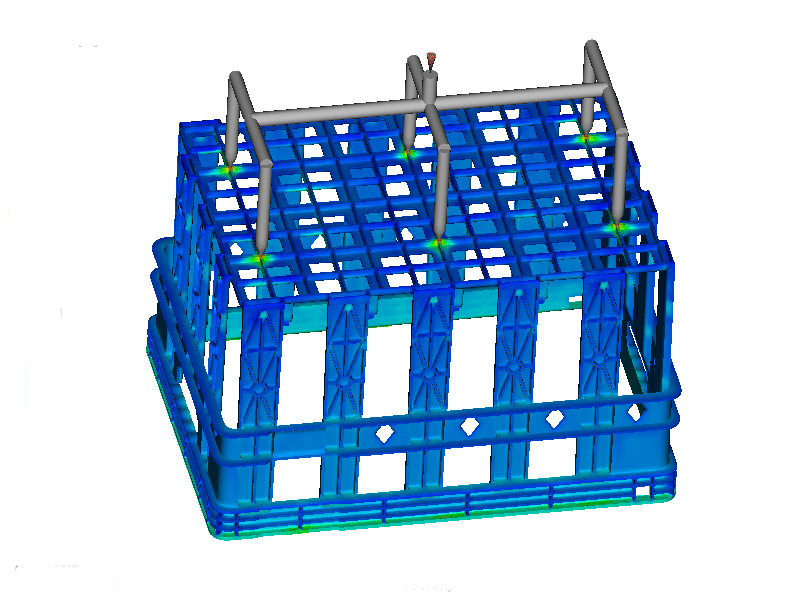

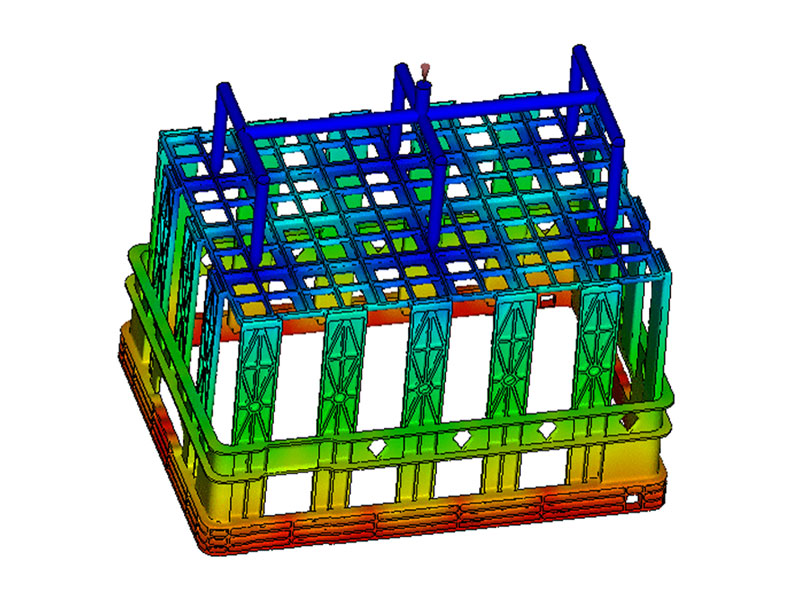

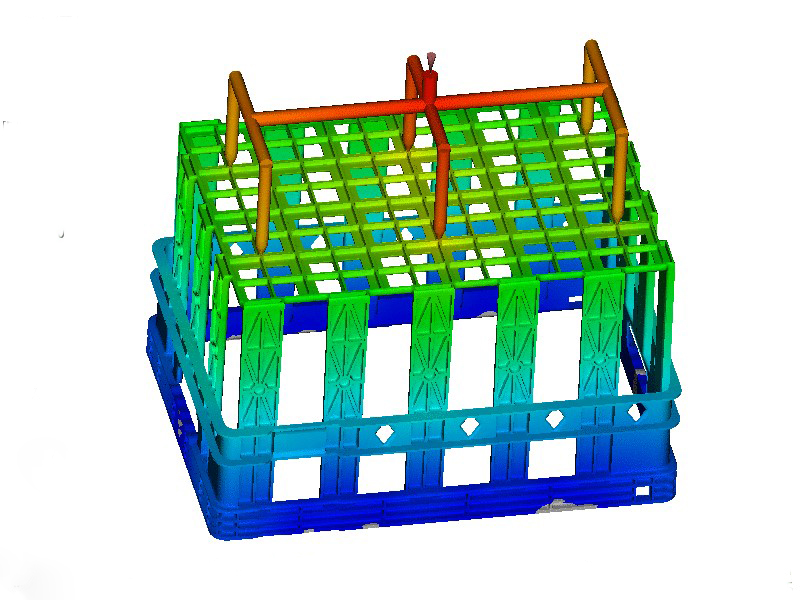

Crate Mould Design | Crate Moldflow

The plastic crate moldflow process starts with designing the plastic based on the desired size and shape of the plastic crate. Once the plastic material has been chosen, a plastic injection machine is used to inject molten plastic into a injection mold that has been designed for the desired shape and size of the plastic crate. During this stage, parameters such as temperature, pressure, speed of injection, and cooling rate can be adjusted depending on the specific requirements of each individual project. The molten plastic will then take its final shape when it cools down in its injection mold. Once cooled, the plastic crate can then be removed from its injection crate mold and inspected for any abnormalities or defects in order to ensure quality control measures have been met before being packaged or shipped out.

Overall, plastic crate moldflow is an efficient way for companies to produce large volumes of consistent high-quality products at low costs due to its automated nature and reduced labor involvement required in comparison to other processes such as blow-molding or rotational casting. Furthermore, it ensures product safety by enabling quality control checks during production without having any risk of manual handling errors occurring which could lead to product deformities or irregularities.

Pressure

Speed

Time

Crate Mold Steel

Crate Mold Steel is a type of steel alloy designed to be resistant to oxidation and corrosion, while having high mechanical strength. 718 and H13 are two of the most commonly used alloys for crate molding, as they have superior wear resistance and hardenability. 718 is an age-hardenable alloy that has excellent creep and fatigue resistance at elevated temperatures, making it especially useful for parts that require longer life in hot environments. H13 is an hot-work tool steel well known for its ability to resist thermal cracking while providing higher toughness than other grades of tool steel. In addition to its strength, Crate Mold Steel is also very affordable compared to other steel alloys. This makes it an attractive option for manufacturers looking to reduce costs without sacrificing quality or performance. Its durability also makes it well suited for repetitive use in industrial applications, where regular maintenance can help extend its lifespan even further.

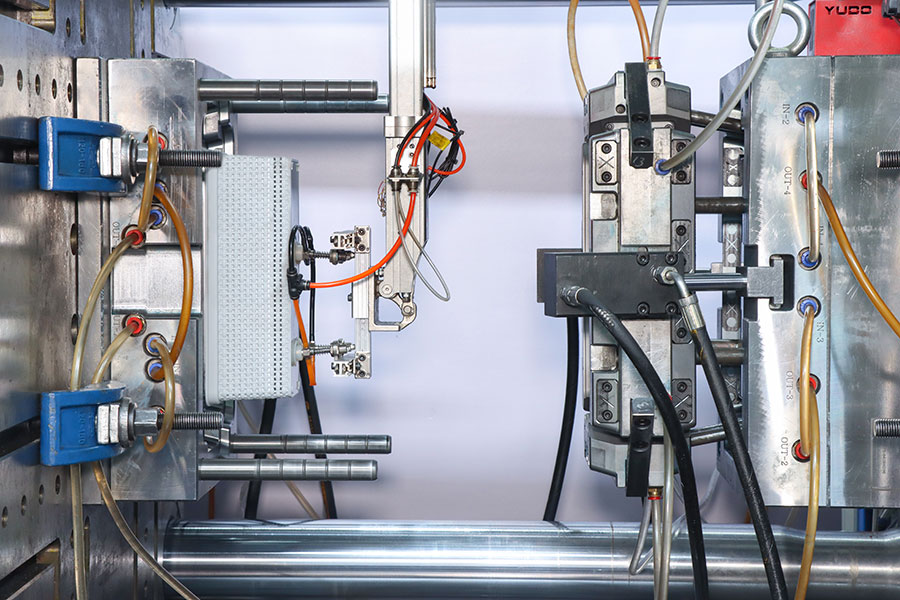

Crate Mold Runner System

The trash can mold adopts multi-point hot runner injection system, usually 2 or 4 points into the gate, the gate for the bottom center position on both sides, multi-point gate can improve the injection efficiency, to avoid the problem of not being able to injection molding, we prefer FOW brand hot runner, the most cost-effective. For more demanding choices, you can also consider YUDO and Husky or Mold Master, which are also more expensive.

Fow Mould | Advantage

Crate Mold Supplier In China

Professionalism

Specializing in injection moulds for 40 years, the number of moulds made is nearly 10,000 sets, and we have accumulated a lot of experience in various aspects such as mould design, processing and production, and mould trial.

Reliability

We treat every customer seriously, keep the customer’s drawings properly, and provide after-sales service for every shipped mold.

Timely

We have a strong sales and after-sales team, and will give a reply to customers’ quotation or after-sales questions within one day.

Cost effective

We have complete production equipment, stock enough raw materials, and strictly control production costs in all aspects of production to provide cost-effective services to our customers.

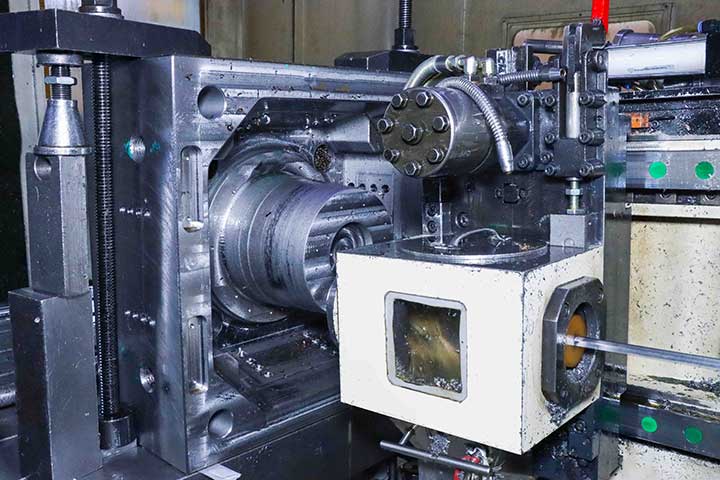

Crate mold processing

FOWMOULD has a full range of processing equipment, with a total of over 100 sets, 95% of the processing is done in the factory, which can meet the production of over 900 sets of molds per year, with total exports to more than 120 countries. Trash can molds are made about 20 sets per year, the largest mold size is 2500x2000x1500mm.

Lathe

Grinding machine

Wire-electrode cutting

CMM

Polish

Injection

Crate Mold product list

We make more than 900 sets of molds per year, with total exports to more than 120 countries.

The shortest mold making time is completed in 4 days, and the largest mold size is 2500x2000x1500mm.

Fow Mould has been in the plastic XXX mould production business for more than 10 years, making it one of the leading manufacturers in China. Our company is one of the largest and most reliable suppliers of XXX moulds, all across the world.

Frequently Asked Questions

60L trash can mold need 800-1000T injection machine

120L trash can mold need 1600T injection machine

240L trash can mold need 2400-2800T injection machine

60L trash can mold price is about 50000-80000USD

120L trash can mold price is about 80000-120000USD

240L trash can mold price is about 150000-180000USD

The final trash can mold price is base on mould material, mould cavity, hot runner brand, and mould structure.

We suggest to use 2 or 4 point hot runner to make the trash can mold. The hot runner brand is base on your cost budgeting.

Usually it takes 60-75 days to make the trash can mold, if the structure of the mold is simple, it can be finished in 50-65 days, if the structure is complicated, it takes 70-80 days to finish.

First, find the problem of the mold, if some spare part broken, such as wear block damage, hot runner damage and so on, you can contact the manufacturer to provide the new spare parts.

If it is a crack in the mold, or some unsolvable problems such as leakage of glue, you can contact the manufacturer to do the mold rework processing, or repair in the manufacturer’s cooperation with foreign repair points, the cost can be negotiated with the manufacturer.

If there is a more serious quality problem that can not be repaired, you can contact the manufacturer to return the mold or redo a new molds.

It depend on the mould material and structure.

500000shots for P20 mould material.

800000shots for 718 mould material.

1500000shots for 2738 mould material.

First is to see the design ability of the team, need product designer and mold designer.

Second is to see the processing equipment, trash can mold is relatively large, the required CNC processing equipment stroke in more than 1.5 meters, also need a large deep hole drill to do waterway processing, if there is no such equipment, it is difficult to do this kind of mold.

Finally, you also need to see if the mold company has experience in producing such molds, such as trash can molds in the processing of various details need to pay attention to, no experience manufacturers are difficult to do a good job.

Usually the payment is 50% in advance and the remaining 50% before shipment.

Since the trash can mold is relatively large, the payment can be 40% in advance and the remaining 60% before shipment.