China Injection Mold Manufacturer Since 1982

Professional in making OEM injection mold 120 countries.

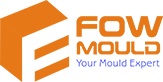

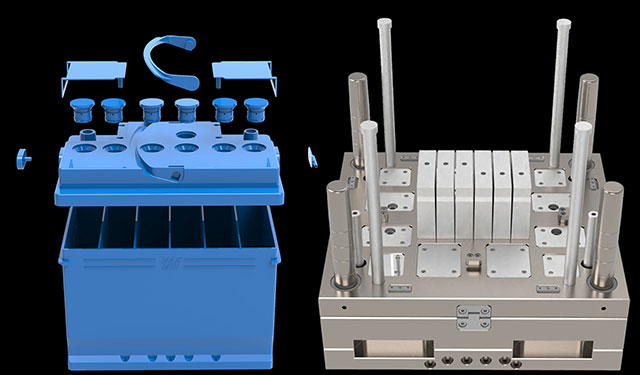

Injection Mold

We make more than 900 sets of molds per year, with total exports to more than 120 countries.

The shortest mold making time is completed in 4 days, and the largest mold size is 2500x2000x1500mm.

precision mould

One-Stop Plastic Injection Mold Services

Design

Design

-

Product Design

- Analysis of shrinkage rate

- Wall thickness analysis

- Analysis of demoulding inclination

- Product structure analysis

-

Mould Design

- Gate runner analysis

- Cooling system analysis

- Ejection system analysis

- Mold flow analysis

-

3D Printing

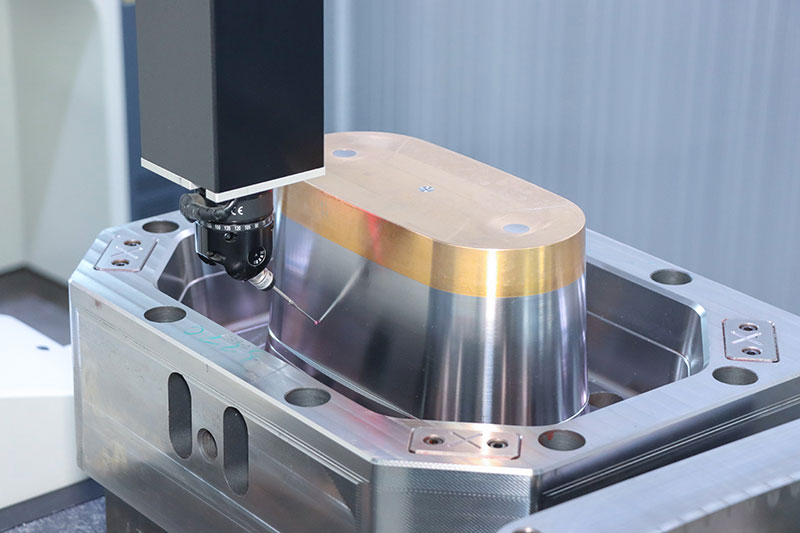

Processing

We totally have 105 equipments and 95% of the machining is done in house.

Machining maximum stroke is up to 2000x1300x800mm.

Machining tolerance is up to 0.0025mm.

Machining progress can be checked in any time.

- CNC

- EDM

- Wire Cutting

- Lathe

- Grinder

- Deep Hole Drill

- Polish

Processing

We totally have 105 equipments and 95% of the machining is done in house.

Machining maximum stroke is up to 2000x1300x800mm.

Machining tolerance is up to 0.0025mm.

Machining progress can be checked in any time.

- CNC

- EDM

- Wire Cutting

- Lathe

- Grinder

- Deep Hole Drill

- Polish

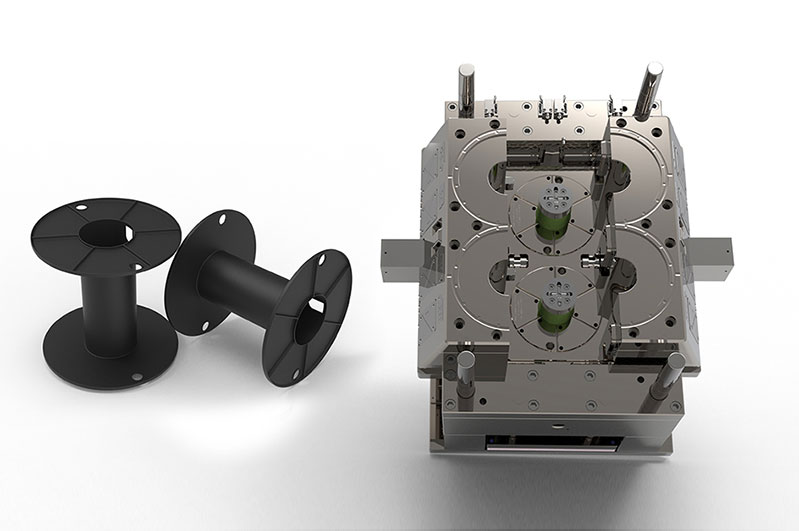

Inspection

Inspection

We strictly control every process in the mold machining, especially in the following 5 links.

- Design inspection

- Steel material inspection

- Machining accuracy inspection

- Sample inspection

- Goods inspection before shipment

Mould Test

We will check the mold operation and record the process parameters when the mold is finished and assembled.

-

Mold operation inspection

- Product forming condition

- Mold ejection condition

- Mold cooling condition

-

Process parameters recording

- Cycle time

- Temperature

- Pressure

- Speed

Mould Test

We will check the mold operation and record the process parameters when the mold is finished and assembled.

-

Mold operation inspection

- Product forming condition

- Mold ejection condition

- Mold cooling condition

-

Process parameters recording

- Cycle time

- Temperature

- Pressure

- Speed

Market Distribution

20%

20%

20%

10%

5%

Customer Evaluation

Cooperation since 2011

ABS pots

Cooperation since 2014

PA6 insert parts mould

Cooperation since 2016

PC transparent parts mould

Why Choose FOW Mould

Information

Confidentiality

We sign an NDA with every clients to keep their information confidential. We ensure that our customers do not have to worry about information leakage.

Progress

Control

We have self-developed production management system, which can fully follow up the production of molds to ensure that the molds are completed on time and improve production efficiency.

Excellent

After-sales Service

We provide global after-sales service and technical support for any quality problems of the mold and products.

All business begins with conversation

- Taizhou Huangyan FOW Mould CO., LTD.

- No.328 Xiaoliqiao Village, Beiyang Town, Huangyan, Taizhou, Zhejiang, 318024, China

- Email:harry@fowmould.com